Czech companies monitor their energy consumption, but not meticulously enough. This results in unnecessarily high operating costs month after month. Although half of the respondents in Soitron’s survey said that energy prices significantly affect their margins, with another 5% admitting severe financial struggles with energy costs, only few companies diligently track their consumption. Yet, simply monitoring consumption and breaking down costs by specific energy sources can eliminate inefficiencies and save up to a tenth of their operating costs.

High inflation and unclear future prospects have plagued Czech companies for over a year. One of the most effective solutions for saving costs is to monitor their energy consumption. “Just observing consumption alone motivates companies to think about how to avoid unnecessary losses of expensive energy,” says Martin Hummel, IoT specialist and product manager at Soitron, a leading IoT integrator operating in the Czech Republic and Slovakia.

It would suffice to switch off machines that are momentarily not in use and consider the choice of new equipment in the future. Or use automation to automatically help reduce energy consumption.

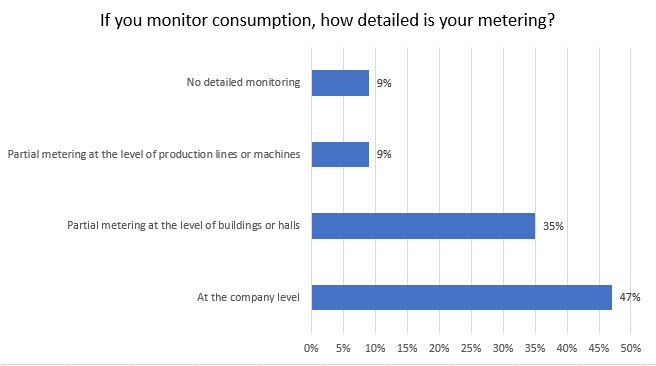

A Soitron survey with 86 participating companies reveals that almost every company (92%) tracks their energy expenditures. Those not monitoring consumption either claim they do not need this data or lack the necessary equipment to collect it.

As for companies monitoring their energy consumption, their approach varies. Some companies primarily look at data for the whole company (47%); more than a third (35%) monitor consumption through secondary metering at the building or individual hall level; and only 9% monitor through secondary metering at the level of individual lines and machines. The remaining respondents do not concern themselves with the detailed breakdown. Depending on the size and type of the company, they are unnecessarily losing up to hundreds of thousands of Czech crowns per year. These inadequately-spent funds could be better used for further development, bringing about both savings and the simplification of day-to-day work.

This problem can be solved by implementing an energy management system, commonly used in modern operations to manage and optimise energy consumption. The first steps to monitoring and managing energy consumption are inexpensive. “The metering system monitors the consumption of the technologies, heating, cooling or lighting in real time. It is thus able to quickly identify specific points of inefficiencies, such as the lights turned on in an empty building. In several implementations, companies have reduced their consumption by 5 to 10% just by obtaining this data alone. So, their investment was paid back in a matter of weeks,” explains Hummel.

The key factor for most companies is to save on production costs. For 60% of respondents, the amount of total energy consumption is the most important, possibly in combination with the price of energy on the spot market, and possible penalties for exceeding their 15 min maxima. Companies follow their energy consumption and energy prices and optimise their production processes based on these factors. Production profitability, i.e. the ability to produce a product for less than what it sells for, is an important indicator for one-third of respondents (34%), suggesting that everything is working as it should.

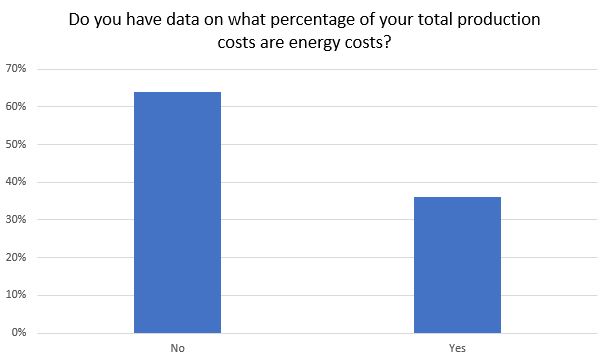

However, the majority of companies (74%) do not use any specific system to collect and analyse energy consumption data. Those that do use data collection claim that having such data is useful. “Any software that enables accurate data analysis is worth it,” declares Hummel. Five percent of the respondents who said they could not manage without external help also admitted that they had no idea what percentage of the total cost of a product is the energy cost. Another five percent of companies was unable to assess the impact of high energy prices on the profitability of their production. To such companies, data collection would provide the easiest help.

We are in the process of finalizing. If you want to be redirected to our old version of web site, please click here.